Good Weld vs. Bad Weld Everything You Need to Know ( Spring 2023)

This is the number one culprit of a bad weld. And generally occurs in all types of welding i.e. Mig Welding, TIG Welding, Stick Welding, Oxy Welding, etc. 4. Undercutting. Undercutting in welding is the condition when the base metal or material is melted away where the next weld bead is to be deposited and thus results in a sharp nook.

HOW TO SPOT A GOOD WELD VS. A BAD WELD in 2021 Weld, Spots, Bad

When it comes to welding, there's good weld vs. bad weld.A good weld is essential if you want a strong product, and strong welds require a lot of skill. Having a welding certification will help you and your clients, but there are many ways to ruin a weld; bad equipment, bad setups, and even the wrong type of welding electrode can ruin a good weld.

Good Weld vs Bad Weld 4 Methods for Proper Results and Testing Advice

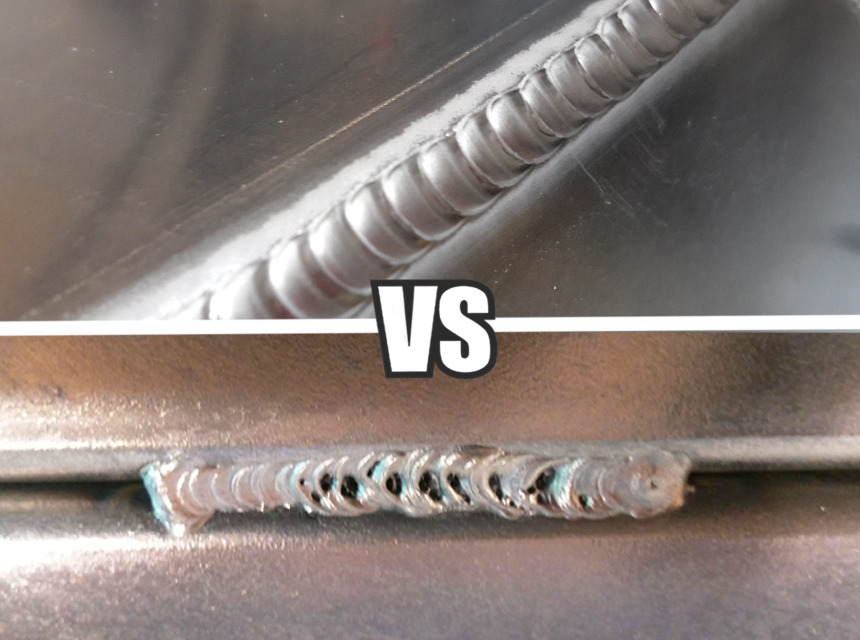

Characteristics of a Bad Weld. A bad weld will often be inconsistent and have visible defects. Some of the common characteristics present in a poor weld include the following: Cracks: Cracking is a common issue for welders and can occur when welding professionals apply too much pressure or if the materials cool too rapidly. If you see cracks.

Good vs Bad Welding An Important Guide for Welders

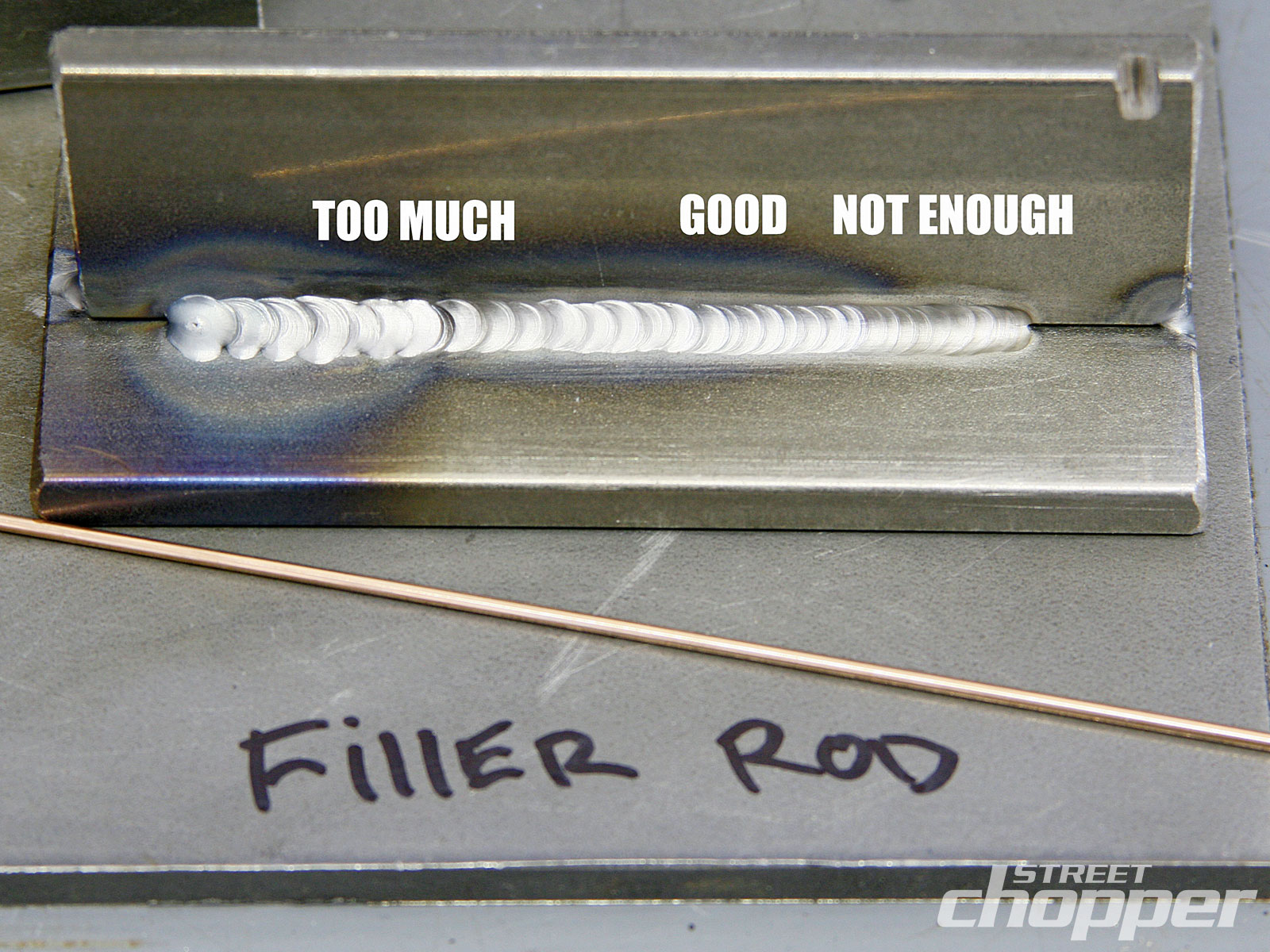

Inaccurate torch adjustment, incorrect flame, travel speed, and improper weld surface cleaning can all have an impact on the weld bead produced by oxyacetylene. A good bead, on the other hand, is one that is consistent and free of flaws like holes or cracks. Good Weld. Smooth bead. No cracks or holes.

A Good Weld vs A Bad Weld Black Bull Engineering

It is simple to determine a good weld vs bad weld. A good stick weld will be straight and uniform. The thickness won't change drastically and there won't be drops of spatter. There are no holes, breaks, or cracks in the bead. You can tell a stick weld is sub-par if there's visible spatter, cracking, undercutting, breaks in the bead, or an.

How can you Identify Good Weld vs Bad Weld

5 Characteristics of A Bad Weld. When you look at a good weld vs bad weld, you will notice five key differences that indicate poor quality. The weld joint will look messy. There may be uneven joints. A physical test may indicate weakness and movement. There may be jagged edges.

Identify good quality welder in welding Industry IME Technology Sdn Bhd

In this article, we'll explain what makes a good weld and why it's important to be able to differentiate between the two. Good Weld. Bad Weld. Smooth and uniform appearance. Rough and irregular appearance. Strong and consistent weld bead. Weak and inconsistent weld bead. Proper penetration and fusion of base metals.

How to Spot A Good Weld vs Bad Weld

How Can You Tell Good Weld from Bad Weld? A good weld will have a smooth, even appearance and will be free of any cracks or voids. A bad weld, on the other hand, will be uneven, have visible cracks or voids, and may even be discolored. If you are unsure of the quality of a weld, it is always best to have it inspected by a qualified welding.

Good Weld Vs Bad Weld Importance of Good Weld!

The quality of welds can have a significant impact on the safety, reliability, and longevity of fabricated products. A good weld can ensure that the product can withstand the stresses and strains of its intended use. A bad weld can compromise the integrity of the product and lead to failures, accidents, or injuries.

20+ Good weld vs bad weld meme Memes Feel

Good Vs Bad Weld. MIG Welding has simplified welding to a great extent and made welding easier for even beginners to learn quickly. Since the skill level required is much lesser for MIG welding, many people are taking up Metal Inert gas welding with limited training. But even though the process is simplified, it still can cause bad welds if the welding procedure is not followed properly.

Shan's GTAW (TIG) Blog. Good Weld Bad Weld Metallurgy

Examples of Bad Welds. Example of a Bad Weld: Start/stop inconsistency. The shape should be consistent and even with a plane that does not display any protruding bumps or peaks. Inconsistent weld width, shape and height example. Again, depending on the welding method, a bad weld will vary in appearance as below.

20+ Good weld vs bad weld meme Memes Feel

A good TIG welding weld bead fuses perfectly with the base metal has a consistent bead width, and is distortion-free. A porous output, lack of pattern, or typical sloppiness is an indication of poor TIG welding. Bad TIG welds may display irregular bead shape and width, excessive spatter, or a visible lack of fusion.

How to Identify a Good Weld vs Bad Weld (with Pictures) WaterWelders

Inclusion of tungsten in the weld. Weld defects. Shielded Metal Arc Welding (Stick Welding) Stick Welding is relatively easy to learn and works with several materials, including carbon steel, stainless steel, cast iron, copper, and aluminum. The following are signs of good stick welds: Consistent thickness. No spatter.

How to Identify a Good Weld vs Bad Weld (with Pictures) WaterWelders

A good weld is one that is strong, uniform, and of high quality, while a bad weld is weak, inconsistent, and of poor quality. Let's take a closer look at the differences between the two. 1. Weld Quality. The most important factor that distinguishes a good weld from a bad weld is the quality of the weld itself.

Good Weld vs Bad Weld 4 Methods for Proper Results and Testing Advice

A good MIG weld is easy to distinguish. The weld is straight and uniform with no slag, cracking, or holes. There are no breaks in the weld, it isn't too thin and there are no dips or craters in the bead. Unlike a TIG weld, a MIG weld has no specific pattern as it is as smooth as possible.

Bad Weld vs Good Weld, 1F Plate Stick Welding, SMAW Welding welder junior YouTube

Use a 5-10 degree push angle when holding the MIG torch for welding. Good Stick Welds Vs. Bad Stick Weld. Stick welding can be used on rusted, dirty, or painter surfaces, unlike MIG welding. But just like MIG welding, there are ways to identify a good vs. bad stick weld. These are.